Yesterday (30 September 2024) saw the last liquid iron tapped from Blast Furnace 4 and the last steel from the traditional ironmaking route cast into slab as Tata Steel UK starts its transition to scrap-based, low CO2, electric arc furnace steelmaking.

The Port Talbot site’s Sinter Plant, Blast Furnace 4 and steelmaking operations were brought to an end calmly and safely, along with the associated energy systems and internal logistics infrastructure.

The remaining two continuous casters, which turn liquid steel into solid slabs, have been paused in advance of a significant investment and will resume operations in line with the commissioning of the new arc furnace in late 2027 / early 2028.

There will now be an extensive period of decommissioning while customers continue to be serviced through the Port Talbot rolling mills and downstream business units using imported slab and hot rolled coil.

In a message to employees, CEO Rajesh Nair said: “I am deeply aware of how difficult this day has been for everyone associated with our business, employees past and present, contracting partners and the wider community.

“It is an incredibly poignant day and one filled with a great deal of emotion, particularly for those of you who have dedicated your careers to these assets.

"Therefore, it is important to pause, recognise and credit the huge contribution that each one of you has made, both to our business and to the communities surrounding Port Talbot. For decades our heavy end operations have stood at the heart of UK steelmaking, and the commitment and expertise of the teams working on them have been second to none.

“Our dedicated teams have worked incredibly hard, often in challenging and difficult circumstances, to keep our heavy end assets operating safely and reliably. Over the course of many months our teams have also been meticulously planning the complex cessation activities to ensure our assets are decommissioned, made safe and remain safe.

“And today, as we wind down our heavy end operations, I saw the incredible amount of care, commitment, pride and passion from everyone involved. I was struck by a comforting sense of control, calm and composure, as well as a relentless focus on safety. I am incredibly grateful to everyone involved in the planning and implementation of the cessation activities. Rest assured your contributions will not be forgotten.

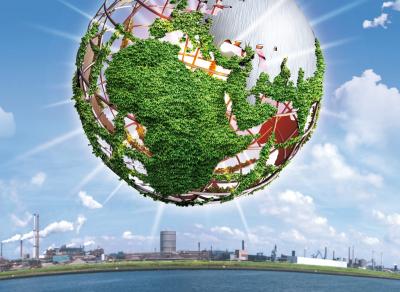

He continued: “As we move towards a more sustainable way of making steel, one that aligns with our commitment to a greener future and allows us to continue producing the high-quality steel we’re known for, I hope we can look to the future with optimism knowing that we are taking the necessary steps to build a greener, more sustainable steel industry, and one that secures our business for the long-term.”

The last of the ‘heavy-end’ asset closures followed the end of operations at Morfa Coke Ovens (20 March), Blast Furnace 5 (4 July), Continuous Caster 2 (12 July), the deep water harbour (2 September) and the site’s ore yards (13 September).

For further information:

- Tim Rutter: tim.rutter@tatasteeleurope.com +44 (0)7850 990755

- Abigail Thomas: abigail.thomas@tatasteeleurope.com +44 (0)7972 575062

- Press Office: ukpressoffice@tatasteeleurope.com

NOTES:

- BF4 was completed in January 1954 as part of a £54 million investment project approved by the Government in 1952.1

- Following its construction, it underwent a number of upgrades and rebuilds including re-linings in 1978 and 1985, total rebuilds in 1992 and 2013.2

- The announcement today is part of a programme that is one of the largest industrial transition projects in the UK. Its implementation has been enabled by the responsible approach of Tata Steel’s workforce, the UK Steel Committee representing the trade unions, and support of the UK Government.

- During the transition period supply chain arrangements in place to serve customers through the transition period until the EAF is commissioned.

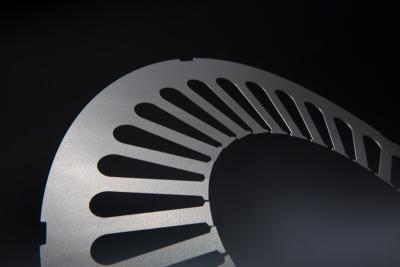

- Equipment orders will be placed shortly for the Electric Arc Furnace (EAF) and ladle metallurgy furnaces, a new coil box and crop shear for the hot strip mill, a cranes package, and for construction management and civil engineering.

- Tata Steel has already launched public consultation on specific activities and is working closely with the authorities to apply for planning approvals by November 2024, with a view to commencing large scale site work around July 2025. The EAF is expected to be operational within three years.

- For employees leaving the business Tata Steel has offered its most generous-ever support package, and a comprehensive voluntary redundancy aspiration process combined with cross-matching and/or re-skilling

About Tata Steel UK

- The Tata Steel Group has been named one of the most ethical companies in the world and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

- Tata Steel in the UK has the ambition to produce net-zero steel by 2045 at the latest, and to have reduced 30% of its CO2 emissions by 2030.

- Tata Steel is the largest steelmaker in the UK with primary steelmaking at Port Talbot in South Wales supporting manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France, Germany and UAE. It also benefits from a network of sales offices around the world.

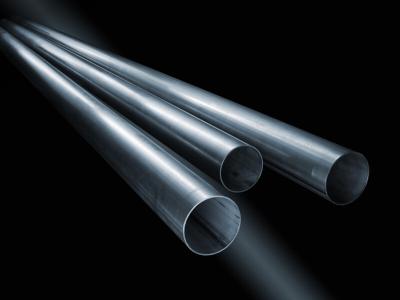

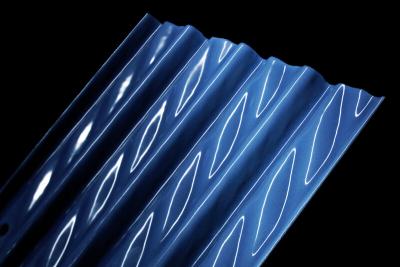

- Tata Steel employs more than 8,000 people and has an annual crude steel capacity of 5 million tonnes, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically diversified steel producers, with operations and a commercial presence across the world.

- The group recorded a consolidated turnover of around US$27.7 billion in the financial year ending March 31, 2024.