EAF at Port Talbot Steelworks

The story so far

Our industry faces significant challenges and many of our iron and steelmaking assets are nearing the end of their operational lifespans, leading to significant production shortfalls and financial losses.

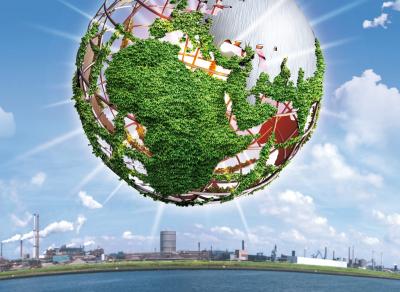

Investment is needed to become a financially, operationally & environmentally sustainable business. European steelmakers are moving away from Blast Furnace steel production and Tata Steel’s ambition is to become a CO2 neutral steelmaker by 2045.

In order achieve this, in September 2023, Tata Steel announced proposals to invest £1.25 billion, including a UK Government grant of up to £500 million, to secure long-term, high-quality steel production at our Port Talbot site, preserving 5,000 jobs and securing steel making in South Wales for generations to come.

The investment will enable our Port Talbot operation to become one of Europe’s premier centres for green steelmaking and includes:

- Building a new 3.2 million tonne capacity state-of-the-art electric arc furnace in Port Talbot, the same capacity as we have now

- Two new metallurgy ladle furnaces alongside upgrading the Casters, Hot Strip Mill and Cold Rolling Mill in Port Talbot

Have your say

We are currently holding a public consultation on the EAF proposals. To discover more about the project, speak to members of the project team and share your feedback join us at one of our community events:

6 – 7 pm, Wednesday 31st July – Online webinar (Click here to register and join)

3 – 7pm, Thursday 1st August, Drop in event at Taibach Community Centre, Duke Street, Taibach, Port Talbot, SA13 1NA

3 – 7pm, Wednesday 7th August, Drop in event at St Paul’s Centre, Gerald Street, Port Talbot, SA12 6DQ

3 – 7pm, Monday 12th August, Drop in event at Aberavon Green Stars RFC, Darwin Rd, Port Talbot SA12 6BS

You can also share your feedback with us by emailing contact@EAFcommunications.com

Project milestones

- Consultation - As we prepare a planning application for the EAF, we will be holding two stages of public consultation to make sure you have the opportunity to understand the proposals and provide us with feedback on the planning application. The initial public consultation is currently taking place and a statutory Pre-Application Consultation (PAC) will take place in September.

- Application - We are working to submit the planning application to Neath Port Talbot Council by the end of November 2024 and hope to receive a positive planning decision in early 2025 so construction can begin.

- Construction - Tata Steel has begun preparations to place equipment orders for the Electric Arc Furnace by September 2024 and based on current permitting timelines, begin construction by August 2025 and for the new furnace to be ready for operation by late 2027.

- Operation - The agreement involves National Grid building new electrical infrastructure capable of powering the 3.2 million tonne Electric Arc Furnace by the end of 2027.

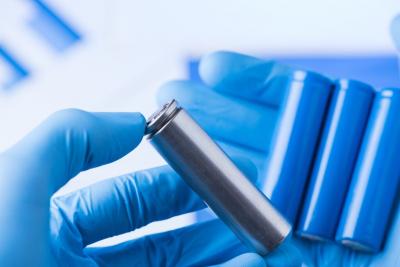

A: Electric arc furnaces use high-current electricity to melt predominantly scrap steel.

The current iron and steel making processes at Port Talbot largely use iron ore, coal and other carbon-intensive fuels.

Using electric arc furnace technology, Tata Steel will reduce carbon emissions from its Port Talbot site by 5 million tonnes a year by 2030 – equivalent to the carbon footprint of almost 2 million homes in the UK (almost one in ten of all homes in England and Wales).

A: The EAF will be placed in the existing Basic Oxygen Steelmaking (BOS) plant.

A: The scrap metal for the EAF will be sourced from the UK helping to maintain the country’s self-sufficiency in steelmaking and making our steel production more resilient to adverse global events. The scrap will be transported into site primarily using the existing rail line. This compares to more than 90% of the raw materials required for the current process being imported from a small number of suppliers in countries as far away as Japan, Brazil, and Australia.

How will using the EAF cut emissions?

The current iron and steel making processes at Port Talbot largely use iron ore, coal and other carbon-intensive fuels, making Tata Steel the UK’s largest CO₂ emitter, which is why this proposal would have such a major impact on decarbonising Wales and the UK as a whole.

As only electricity is required, which can come from renewable sources, using EAF rather than the existing blast furnaces will cut carbon emissions by almost 90%. This is equivalent to 1.5% of the UK’s total direct CO2 emissions.

A: The current iron and steel making processes at Port Talbot largely use iron ore, coal and other carbon-intensive fuels, making Tata Steel the UK’s largest CO2 emitter, which is why this proposal would have such a major impact on decarbonising Wales and the UK as a whole.

As only electricity is required, which can come from renewable sources, using EAF rather than the existing blast furnaces will cut carbon emissions by almost 90%. This is equivalent to 1.5% of the UK’s total direct CO2 emissions.

A: We are holding community consultation events over the summer where members of the public can find out more about the EAF proposals, ask any questions and share feedback with us. In September we will hold another round of consultation before a planning application is submitted to Neath Port Talbot Council.

Latest news

- 7615129 May 2024Corporate NewsSky News: Steel going green

Tata Steel UK has featured in a recent mini-documentary by Sky News about the challenges and opportunities

-

- 7602620 May 2024Press ReleaseElectricity connection agreed for Port Talbot’s green steelmaking transformation

-

- 759213 May 2024Press ReleasePodcast: American steel giant shows how to go green

-