Quality and flexibility

All products are produced to the highest standards (IATF 16949:2016 certified), and tailored to meet our customers’ needs across a whole range of industries such as construction, agricultural machinery, domestic appliances and general industry. Having direct access to water ensures an efficient and seamless inbound / outbound logistics from our mill all the way through to customers.

We have special gear for cutting numerous flat rectangular blanks simultaneously at different blank widths, from main coils with a max width of up to 1850mm, in thicknesses from 0,3mm to 3mm. Our equipment and processing capabilities meet the highest surface requirement for outer panels for critical products such as full-finish hot-dip galvanised (HDG) and Organic Coated Steel (OCS). MultiSteel is equipped with slitting capabilities starting from minimum gauge of 0,2mm and a min width of 25mm which requires accurate slitting gear and precision tooling.

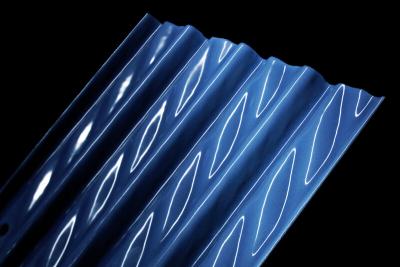

Multisteel can process a variety of OCS products in different forms, including wide and slit coils, multi-strand blanks and add protective films. Colorcoat HPS200 Ultra pre-finished steel combines outstanding performance with exceptional durability. With its market-leading guarantees and excellent sustainability credentials Colorcoat HPS200 Ultra is suitable for many different construction applications.

Location

MultiSteel – located in Maastricht, in the south-east of the Netherlands is close to a harbour. Harbour access ensures efficient, seamless inbound and outbound logistics from our steel mill all the way through to customers.

Technical expertise

Tata Steel product specialists are experienced with our current products and have extensive knowledge about new developed products. We can also support you with the right material selection.

Furthermore we have specialists in all relevant areas of process knowledge and modern state of the art R&D facility.

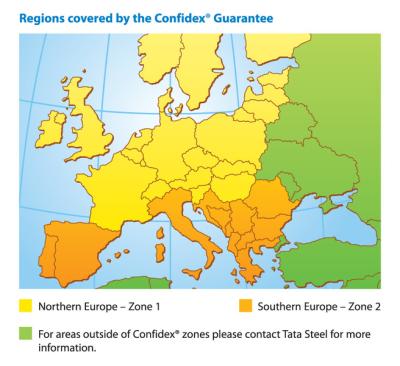

Global support

Our European steel service centres offer access to Tata Steel’s global network of sales offices. This means we can support customer operations throughout Europe and beyond.

Just-in-time delivery

We offer significant experience in meeting the automotive market’s demand for just-in-time deliveries. Our flexibility is combined with excellent geographical reach and technical expertise. This has enabled us to become the preferred route-to-market for both direct and indirect deliveries to original equipment manufacturers and their sub-contractors. Our multilingual teams are here to support you and answer all your queries.

Applications and quality

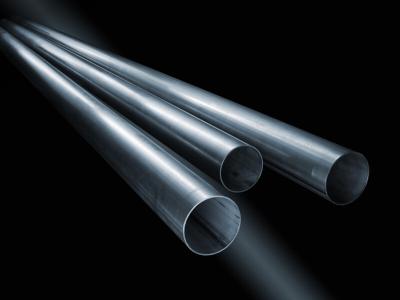

Steel processed at MultiSteel is used for a variety of modern components.

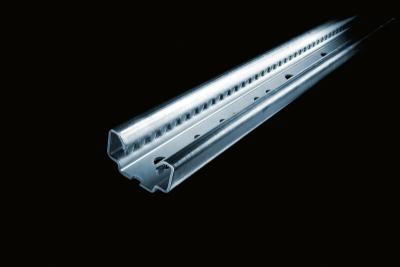

MultiSteel offers a broad multi-metal range for the Automotive industry. Our facilities convert wide and light gauge strip into precision slit coils, de-coiled sheets and multi-strand blanks with widths up to 1.8m, thickness from 0.2-3.0mm and a strength level up to 1000 MPa.

Being an IATF 16949:2016 certified Steel Service Centre, all our products are produced to the highest standards including full-finish capabilities and tailored to meet our OEMs and tier suppliers needs.

Products

We process the following products:

- Hot-rolled

- Ympress®

- Cold-rolled

- Ymvit®

- Ymagine® direct-rolled

- Metallic coated

- Hot-dip galvanised

- MagiZinc®

- Galfan®

- Galvannealed

- Hot-dip aluminised

- Galvalume

- Aluzinc

- Electrozinc-plated

- Pre-finished or organic coated

- Colorcoat HPS200 ULTRA®

- Colorcoat Prisma®

- Laminated

MultiSteel has four production lines at its disposal that provide the possibility to make a wide variety of products. Strip steel and small coils can be produced on slitter 1 and slitter 2, sheet metal on the multi-blanker and small sheets on the mini-blanker.

| Processing unit | Width | Thickness | Comments | ||

|---|---|---|---|---|---|

| Min (mm) | Max (mm) | Min (mm) | Max (mm) | ||

| Slitter 1 | 400 | 1850 | 0.3 | 3 | Up to 40 individual slits across coil width |

| Slitter 2 | 400 | 1550 | 0.2 | 1.5 | Up to 40 individual slits across coil width |

| Miniblanker | 200 | 1050 | 0.3 | 0.8 | Stacking up to 1250mm length blanks |

| Mutiblanker | 300 | 1850 | 0.3 | 3 | Stacking up to 6000mm length blanks |

Maximum strength level is 1000 MPa

Maximum 20t coil weight

Please consult our sales department regarding specific technical feasibility of dimensional combinations, tolerances and grades. You can find details on how to get in touch with us in the 'Contacts' section the the right, or 'Contact Us' below.

Terms and conditions (sales and purchasing)

Sales terms and conditions (English)

Sales terms and conditions (Nederlandse)

Sales terms and conditions (Francais)

Sales terms and conditions (Deutsch)

Purchasing terms and conditions (English)

Purchasing terms and conditions (Nederlandse)

Purchasing terms and conditions (Deutsch)

Certificates and approvals

IATF 16949:2016 certificate (English)

IATF 16949:2016 certificate (Nederlandse)

IATF 16949:2016 certificate (Francais)

IATF 16949:2016 certificate (Deutsch)

ISO 14001 certificate (English)

ISO 14001 certificate (Nederlandse)

ISO 14001 certificate (Francais)

ISO 14001 certificate (Deutsch)

Site instructions

General Safety Regulations (English)

Delivery/pick up regulations (lorry) (English)

Delivery/pick up regulations (lorry) (Deutsch)

Delivery/pick up regulations (lorry) (Français)

Delivery/pick up regulations (lorry) (български)

Delivery/pick up regulations (lorry) (český)

Delivery/pick up regulations (lorry) (Espagnol)

Delivery/pick up regulations (lorry) (magyar)

Delivery/pick up regulations (lorry) (Italiano)

Delivery/pick up regulations (lorry) (Nederlandse)

Delivery/pick up regulations (lorry) (Polski)

Delivery/pick up regulations (lorry) (русский)

Delivery/pick up regulations (lorry) (Türk)

Delivery/pick up regulations (lorry) (norsk)

Delivery/pick up regulations (lorry) (Română)

Delivery/pick up regulations (lorry) (svenska)

Delivery/pick up regulations (lorry) (Српски)

MultiSteel Service Centre

Fregatweg 42

6222 NZ Maastricht

The Netherlands

General Enquiries:

T: +31 (0) 433 688444

E: multisteel@tatasteeleurope.com

EN-Service centres-Contact-Benelux MultiSteel

MultiSteel Service Centre

MultiSteel Service Centre

Fregatweg 42

6222 NZ Maastricht

The Netherlands