Superior quality

NICOR is created by electroplating cold-rolled steel with nickel and diffusion annealing. The heat treatment ensures an inseparable bond between the homogeneous nickel layer and the steel substrate. This delivers benefits in further processing. It also means you can rely on NICOR for semi-finished end-products of superior quality.

- improved end-product functionality

- end-products of consistent and reliable quality

- trouble-free, repeatable processing

- scope to optimise processes

- minimised yield loss

Reliable performance

Tata Steel Plating has proven expertise in the production of nickel-plated diffusion annealed steel and other electro plated steel products. The cold-rolled steel sheet that forms the basis of NICOR® is produced from top quality hot-rolled strip. Rigorous control of our cold rolling, electroplating and diffusion annealing processes means that NICOR offers:

- excellent corrosion resistance

- temperature resistance to over 200°C

- tight tolerances and optimal consistency of layer thickness

- improved corrosion resistance

- extra deep drawing capability

- good scratch and abrasion resistance

- very good further processing characteristics (weldable, brazeable)

- excellent resistance against aggressive fuels such as bio diesel

|

Delivery condition |

Available temper |

Thickness range |

Nickel plating thickness |

Width range |

|||

|---|---|---|---|---|---|---|---|

|

mm |

inch |

μm |

µinch |

mm |

inch |

||

|

A, LC, C290, C340, C390, C440, C490, C590, C690 |

2T, 3T, 4T, 5T |

0.100 – 1.500 |

0.008 – 0.060 |

0.6 – 6.0 |

24 – 240 |

3 – 724 |

0.10 – 28.5 |

|

C999 (DC01 only) |

1T (full hard) |

0.250 – 1.500 |

0.008 – 0.060 |

0.6 – 6.0 |

24 – 240 |

3 – 724 |

0.10 – 28.5 |

Surface appearance

|

Surface Finish |

Code |

Ra (µm) |

Description |

|---|---|---|---|

|

Bright finish (BF) |

KR 0.5 |

≤ 0.2 |

very smooth surface |

|

Fine stone finish |

KR 4 / #2 Finish |

0.15 - 0.45 |

smooth surface |

|

Matte finish |

KR 7 / #1 Finish |

0.6 - 1.8 |

matte surface |

|

Rough matte finish |

KR 8 / #1 Finish |

1.0 - 2.5 |

rough matte surface |

|

Satin finish |

|

|

similar to brush finish |

We can also lacquer satin-finished products on request – please contact us.

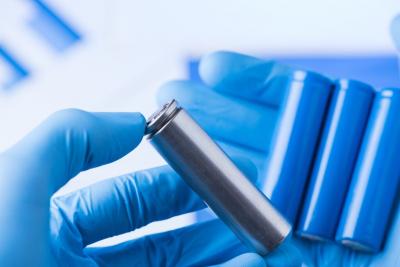

Applications

NICOR is used in a variety of applications in demanding markets:

- Electronic components

- Automotive components

- Telecommunications equipment

- ICT products

- Office equipment

EN-Plating-Contact-Hille and Muller general

General enquiries

Tata Steel Plating

Head Office

c/o Hille & Müller GmbH

Am Trippelsberg 48

D-40589 Düsseldorf