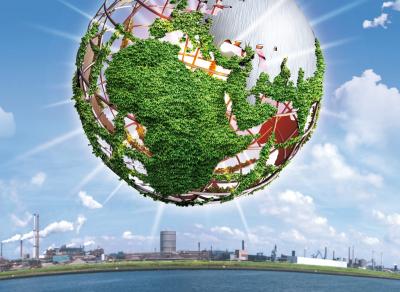

"There can also be no transition to a green economy without a thriving steel industry – almost every aspect of the UK’s decarbonisation plan needs steel. It’s why every G20 economy around the world has its own sovereign steelmaking capability," says Tata Steel UK Chairman Henrik Adam introducing the company's latest sustainability report

In introducing the report, Dr Adam said: "The past few years – with shortages of everything from domestic energy production to computer chips – have held back the UK’s economic recovery and reminded us of the importance of being self-sufficient in critical materials and services.

"Steel is an essential component of the UK’s manufacturing, engineering and construction sectors – responsible for 16% of the country’s economic output. There can also be no transition to a green economy without a thriving steel industry – almost every aspect of the UK’s decarbonisation plan needs steel. It’s why every G20 economy around the world has its own sovereign steelmaking capability.

"Tata Steel recognises that steelmaking has to be sustainable in every sense.

"Thanks to the huge investments that we’ve made in reducing emissions, our Port Talbot plant is ranked in the top third of the most CO2- efficient integrated steelworks in the global benchmark. Despite this, it still contributes 2% of the UK’s overall carbon emissions.

"The UK aims to reach net zero by 2050. For this to happen, we face two choices for the steel industry: It could be allowed to decline. The UK would lose its self-sufficiency and resilience in steel, as well as thousands of well-paid jobs in steel communities. Emissions would fall here, but we would be importing a lot more steel, leading to more emissions in other countries. This is, of course, illogical and undermines Britain’s economy and the global effort to tackle climate change.

"Or we could invest here in transformative technologies to produce steel in a carbon neutral way. This is entirely possible, but it requires support from the UK Government on the same scale as our European neighbours, both in terms of direct investment and electricity market reform to ease the 60% higher energy prices we face here compared to those in Europe.

"Tata Steel wants to help the UK achieve its ambition and its net-zero objectives. We understand the technologies, we have the ambition and we have the people to produce green steel. We are ready to lead the next technological leap forward, and produce sustainable steel for the wind and solar farms, electric vehicles, major infrastructure projects and efficient green buildings of the future. But we cannot do it alone.

"This report shows where we are now, and also a glimpse of where we could be. We are at a crossroads, between letting steelmaking decline and offshoring our emissions, and a new era in which we transform the UK steel production process to make it fit for 2050 and a bright future."

- ENDS -

Case Study: CopETe

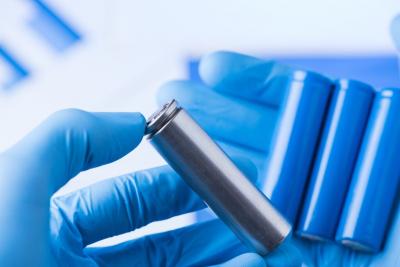

We are one of nine industrial partners and universities in a Jaguar Land Rover led project to create a high-performance compact electric drive unit (EDU) for battery electric vehicles. The three-and-half-year collaboration, known as CompETe, is match-funded by the UK government via the Advanced Propulsion Centre.

Our product engineering knowledge group, working closely with our electrical steel business Surahammars Bruks AB in Sweden, actively supports the EDU designs, especially in characterising ultra-thin non-grain-oriented (NGO) electrical steels, while our computer-aided engineering specialist has developed 2D and 3D models for assessing the high-speed motor rotors’ structural integrity.

Case Study: Celsius

Wind power Offshore wind power is a big success story for the UK, which is now a leading force in this technology.

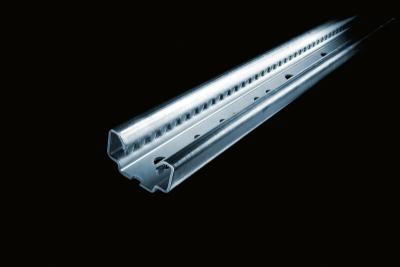

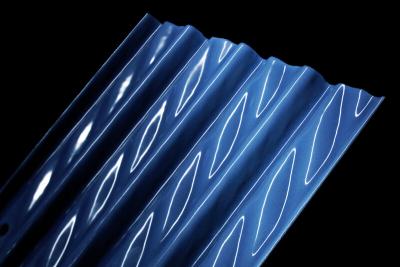

The country has the second largest fleet of offshore wind turbines of any country globally, and its immense growth here is set to continue. Offshore wind turbines use large amounts of steel, and our Celsius® premium structural hollow sections are playing their part in this renewables revolution.

Celsius steel is valued for its properties which make it reliable in the harshest of environments. It can be found in most of the offshore windfarms around the UK, as well as in many off the coasts of Germany, Denmark, Netherlands and even Taiwan.

Case Study: Seismic

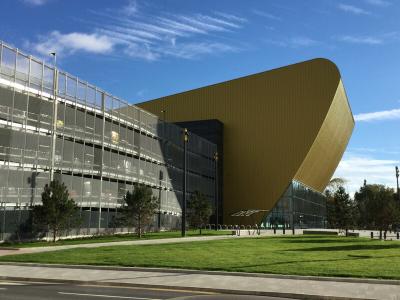

We are partners in SEISMIC II a demonstrator project that uses modern methods of construction (MMC) to make construction more streamlined by using offsite production processes. It examines how components such as the steel frame can be reused and looks at the whole life performance of a building.

With a focus on the public sector, it builds on the success of Seismic I, which showed how a standardised light steel frame could change the way new schools were designed and constructed. Seismic II encompasses the production of wall, floor, ceiling and roof components that are all completely interoperable with the standardised light steel frame.

The completed demonstrator building is a template for high performance buildings of all types, delivered using high quality, reliable, standardised components. While construction steel is regularly recycled now, with nearly all being recycled following demolition, its reuse is still being explored by projects such as this.

Reuse of construction materials could lead to a reduction of 22.3 million tonnes of CO2 (source: The Alliance for Sustainable Building Products) between 2023 and 2034. It is possible, through the development of sophisticated traceability and tracking, that the end-of-life reuse rate for the steel frame will be between 80% to 95%, saving the carbon emissions and costs associated with using new steel.