Works Manager Dean Cartwright explains the process of closing down Tata Steel's Blast Furnace 5 in Port Talbot this week.

Monday 1 July:

“In the coming days we will begin the process of bringing operations at Blast Furnace 5 to a close.

While this is a difficult time for all those who work on the furnace and for all those who have played a part in the life of BF5 over many years, it is a necessary step as we approach the end of life for many of the site’s iron and steelmaking assets.

In the days leading up to the closure, people living in the community might see some steam coming from the top of Blast Furnace 5 (the one on the left as you look at them from the motorway).

As we reduce the volume of raw materials in the furnace it is possible that the quality of the iron is not good enough to turn into steel, and so we might be pouring this into what we call ‘plating pits’ in the ground – there might be some red plume visible from this process.

While this is a difficult time for all those who work on the furnace and for all those who have played a part in the life of BF5 over many years, it is a necessary step as we approach the end of life for many of the site’s iron and steelmaking assets.

At the latter stages of the final day of operations, people should expect to see plumes of steam from the top of the furnace for some period of time – maybe up to 8 hours - along with some whooshing noise (although this won’t be anywhere near the volume of a bleeder opening). It is our intention to carry this out in daylight so as not to disturb people unnecessarily at night.

Rest assured we are continuing to make all the best preparations for this process – it is one we have completed safely many times over the years and our people are experts.

We are very grateful for the understanding of local residents as we go through this closure process, and we will keep communicating with you as timings become more clear.”

Tuesday 2 July:

“We have now started the process of winding down operations on Blast Furnace 5.

We have started to change the burden (the raw materials we put in the top of the furnace) to make sure the slag formed on top of the iron is the right type for this process, and reducing the amount of coal we inject into the furnace.

Today (Tuesday) we are pausing the furnace to install some additional instrumentation to take extra measurements and readings of things such as temperatures, gas content and so on.

Local residents may well see some steam coming from the bleeders – this is the same as when we regularly pause the furnace and is called ‘taking the furnace off-wind’ – a bit like turning down a cooker to simmer.

"Today (Tuesday) we are pausing the furnace to install some additional instrumentation to take extra measurements and readings"

In the coming 24 hours we will return the furnace to ‘on-wind’ and continue to tap liquid iron as usual.

In the next 48 hours we will stop adding new raw materials and bring the burden down to low levels within the furnace. It is at this stage that local residents will start to see much larger plumes of steam coming from the top of the furnace, accompanied by some prolonged whooshing sounds. This is absolutely standard procedure and nothing to be concerned about.

At every stage of this process, we have our experts monitoring every aspect of the process to make sure we bring the furnace to a close calmly and safely.

I shall keep you informed throughout the coming days.”

About Tata Steel UK

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

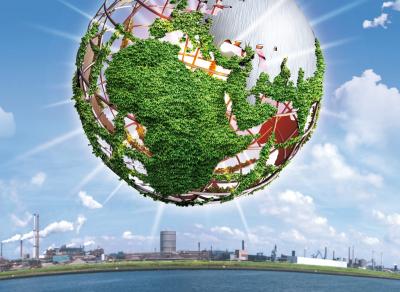

- Tata Steel in the UK has the ambition to produce net-zero steel by 2045 at the latest, and to have reduced 30% of its CO2 emissions by 2030.

- Tata Steel is the largest steelmaker in the UK with primary steelmaking at Port Talbot in South Wales supporting manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France and Germany. It also benefits from a network of international sales offices around the world.

- Tata Steel employs more than 8,000 people and has an annual crude steel capacity of 5 million tonnes, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

Follow us on social media