A Wales-centred industrial collaboration, led by Swansea-based Marine Power Systems, has been awarded nearly £1 million of innovation funding.

The project is to develop the use of low CO2 steels from Tata Steel’s Port Talbot site to build platforms for floating offshore wind structures and strengthen local supply chains.

The Launchpad project is a collaboration between Marine Power Systems (MPS), Tata Steel UK, Swansea University, Associated British Ports and leading engineering and fabrication company, Ledwood Engineering.

The funding from Innovate UK, the UK’s Innovation Agency, is to further develop and optimise PelaFlex, Marine Power System’s unique and flexible floating offshore wind platform, for applications in the Celtic Sea. The project also aims to ensure that the material sourcing, fabrication, manufacture, and product deployment is maximised through local supply chains.

Graham Foster, MPS Chief Technology Officer commented: “We are confident that through this project we will be able to optimise our platform design to increase the amount of local, low CO2 steel used for each platform from around 10% to over 50% - that could be as much as 50,000 tonnes of steel each year, based on ongoing supply into Celtic Sea floating wind projects.”

“With the deployment of floating offshore wind in the Celtic Sea becoming a reality, the time is absolutely right to work with local supply chain partners and top research establishments to optimise the detailed design of our technology and maximise its deliverability.

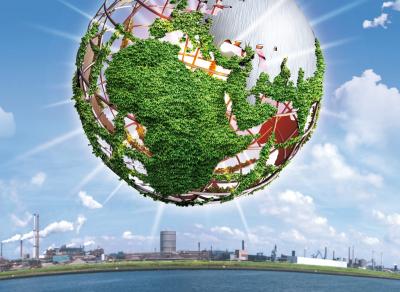

Tata Steel UK’s CEO Rajesh Nair added: “We have a vision for our future low CO2 steels to be at the centre of a green industrial hub here in South Wales. Collaborations with industrial partners such as MPS demonstrate the huge potential benefits of producing green steels as well as providing security for local supply chains and the communities that surround us.”

Mark Davies of Ledwood Mechanical Engineering continued: “The project represents another step forward for the emerging floating offshore wind industry. As a locally based engineering company, we are pleased to be working with MPS, Tata Steel, the Port of Milford Haven, ABP Port Talbot and Swansea University to help build a local supply chain by capitalising on the skills, expertise and infrastructure that we have here in South-West Wales. This is an exciting time for us and we hope the region can take advantage of the opportunities that will soon emerge.”

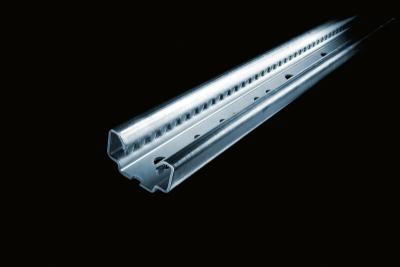

Specifically, the project will optimise the structural efficiency of MPS’s floating offshore wind platform, PelaFlex, paying particular attention to the challenging environment in the Celtic Sea whilst minimising both the cost of materials and deployment. That includes the use of strip steel manufactured in Port Talbot, the use of components fabricated by local suppliers and the assembly and roll out using existing ports in the southwest Wales.

Swansea University will provide design input by applying the latest developments in structural design modelling, and Ledwood, based in Pembrokeshire, will provide feedback that will help maximise the extent to which fabrication can be supported from local suppliers. Input from Associated British Ports and the Port of Milford Haven will ensure that the platform can be assembled and deployed from those locations whilst minimising the investment required to do so.

The UK Government, supported by the current 4.5GW licensing round for floating offshore wind in the Celtic Sea, has committed to delivering 5GW of floating offshore wind by 2050.

The Labour Party Manifesto 2024 states that to achieve clean power by 2030, they would “Pioneer floating offshore wind, by fast-tracking at least 5 GW of capacity.”

-ends-

WATCH / LISTEN:

You can listen to or watch the latest SteelCast podcast where Tata Steel and MPS discuss the project in more detail here:

YouTube: https://youtu.be/epkeUfycZ34

NOTES:

- MPS is exhibiting at the Global Offshore Wind conference in Manchester

Programme (renewableuk.com) on 18-19 June 2024, which is being opened by Rt Hon. Alok Sharma, President of COP26 - MPS is the leading UK-based floating wind technology developer and has already built strong relationships with both energy developers bidding for seabed in the Celtic Sea and local supply chain partners.

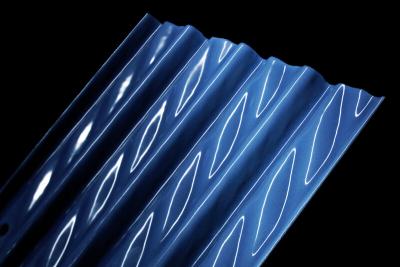

- Marine Power Systems’ advanced floating platform technology, PelaFlex, supports the rapid deployment of industrial scale floating offshore wind whilst maximising local content delivery through existing supply chain. High system stability, low overall mass and zero tilt maximises energy yields, allows for simple installation using standard vessels and increases operation and maintenance weather windows. Multiple launch options and shallow draft support a distributed port model for faster deployment and reduces the need for specific port requirements.

About Tata Steel UK

- The Tata Steel Group has been named one of the most ethical companies in the world, and is among the top producing global steel companies with an annual crude steel capacity of 34 million tonnes.

- Tata Steel in the UK has the ambition to produce net-zero steel by 2045 at the latest, and to have reduced 30% of its CO2 emissions by 2030.

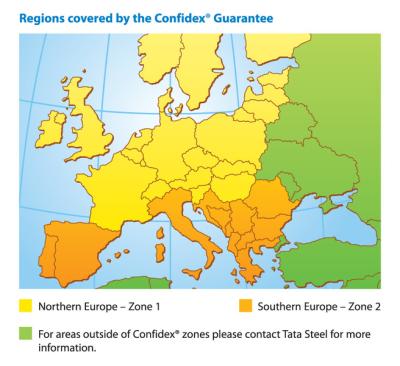

- Tata Steel is the largest steelmaker in the UK with primary steelmaking at Port Talbot in South Wales supporting manufacturing and distribution operations at sites across Wales, England and Northern Ireland as well as Norway, Sweden, France and Germany. It also benefits from a network of international sales offices around the world.

- Tata Steel employs more than 8,000 people and has an annual crude steel capacity of 5 million tonnes, supplying high-quality steel products to demanding markets, including construction and infrastructure, automotive, packaging and engineering.

- Tata Steel Group is one of the world's most geographically-diversified steel producers, with operations and a commercial presence across the world.

Follow us on social media